The medical device market is large, complex, competitive, and growing. As a global development and production partner for the European, Asian and US markets, we strive to remain aligned with the latest market developments. In this blog article, I will take a closer look at the orthopaedic device market and describe three of the top trends as well as speculate about what the future might hold.

1. Cost control: Commoditization of the orthopaedic device market

The first big trend I see is that the orthopaedic device market – in many ways – is becoming more commoditized and there is a larger focus on cost-reduced implants, instrumentation and delivery systems. This is the result of the combined effect of ongoing pricing pressure and growing demand for procedures in the market – medical device companies must find ways to reduce the cost of getting their products into the hands of the people who need them around the globe. Cost controls are becoming even more important because expanding regulatory requirements are generating increased expense which erodes margins even further. As a result, medical device companies have to work really hard to eliminate non-value added cost drivers and mitigate supply chain and regulatory expense.

We focus on building effective and sustainable quality and regulatory processes

At Elos Medtech, we recognize that by investing time and resources early in the project, there is a greater opportunity to develop a compliant and cost effective design and supply chain from the very beginning. Furthermore, we are continuously working to increase internal efficiency, improve production techniques and utilize technology advances to support our customers’ ongoing cost containment activities. Aside from the design, manufacturing and logistics processes, we understand that one of the greatest cost drivers of any project or product is the ever escalating regulatory compliance aspect. At Elos Medtech, we are highly knowledgeable of the requirements and capable of full compliance in a cost effective, value added manner. We truly believe that companies who are able to comply in a simple and efficient way will have a serious competitive advantage. This is why building effective and sustainable Quality and Regulatory processes is a large focus for our group.

2. Product innovation: Improved patient outcomes, reduced surgical time

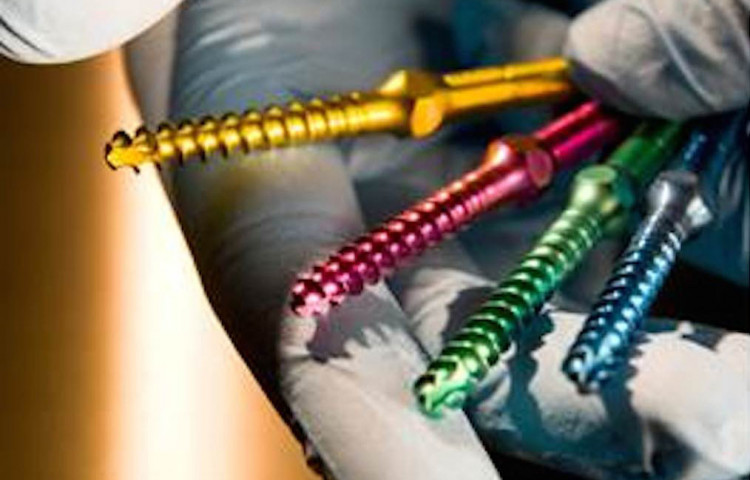

Improving patient outcomes and reducing procedure time is also becoming increasingly important in healthcare. And within the orthopedics market, we have an ageing population that is going to need more procedures. It is actually expected that there will not be enough orthopaedic surgeons to meet the growing demand. Device companies are going to have to produce medical devices and tools that allow orthopedists to perform more surgeries, which in turn also reduces cost. Medical devices need to be simpler and more user friendly with less likelihood of error. But they cannot cost more, and this is also a challenge. Most products on the market today are generally sufficient. So unless a new product can reduce the surgical time or improve patient outcomes or differentiate itself in some meaningful way, hospitals are typically unwilling to pay more. A large challenge lies ahead for the medical device companies to effectively compete and meet the demands of the market.

We collaborate closely with customers to improve performance, cost and quality

In close collaboration with our customers and their development teams – and within our niche areas of expertise – we use our deep knowledge to help design and deliver products that will perform better and which will meet the surgeon and patients’ needs. Understanding the specific surgical application and the associated challenges along with the market requirements of the customer is essential to our process. The earlier our team can be brought into the commercial, design and R&D process, the more opportunity we will have to provide suggestions for improved performance, optimal cost control and advance consideration of quality compliance requirements.

3. Technology advances: Robotics, computer-aided surgery, 3D printing

Today, we are seeing a number of technology advances in the orthopaedic device market. We definitely see more emphasis on minimally invasive, computer aided and robotically assisted surgery with the goal of improving accuracy, precision and patient outcomes. Over time, this may help create a higher and more replicable standard of care and perhaps one day help to achieve the broad goal of reducing surgical time and the total cost of care. As the technology moves forward, the orthopaedic supply chain needs to keep pace. In the end, one thing remains constant. When it comes to orthopaedic procedures, there will always be the need for medical devices and tools that can cut, shave, and make holes in bone.

Another technology that is a subject on everyone’s lips right now is 3D printing. Even though not widespread, we are starting to see 3D printing in orthopaedic procedures and manufacturing for prototype, custom and low volume solutions. One of the greatest advantages of 3D printing is that implants can be completely adapted to the patient, and delivered with a very short time frame. But because the implants are patient-specific, and quite expensive to produce, this technology targets a smaller niche market.

We develop our knowledge with 3D manufacturing techniques continuously

We are already helping to develop and deliver many products in support of robot assisted and computer assisted surgery (such as for fixation and bone cutting,) and working with customer design teams to develop products to support their growing needs within this surgical area. It is a natural fit for our specialized expertise. We are also working to apply 3D manufacturing within our groups. Currently, our efforts are focused on supporting production innovation and process improvement activities but we are continuously developing our knowledge and experience with 3D manufacturing techniques to evaluate applications that could be directly applied to the products we deliver in the future.

The US orthopaedic device market and the future

So what does the future hold for the US orthopaedic device market? This is always a difficult question to answer, but I definitely think that the market will only continue to experience steady development as the population continues to grow and to age and the demand for orthopaedic devices increases. One of the biggest challenges ahead will probably be for the companies to differentiate themselves. As to the technology advances, they are not likely to slow down. On the contrary, new innovations will go hand in hand with the need for improving patient outcomes, reducing surgical time and hopefully also the total cost of care. And while the US has heavily dominated the global market for some time now, companies that are able to compete in a cost effective way and deliver innovative and regionally tailored solutions will have a competitive advantage. Ultimately, technology is and will continue to be one of the key drivers for overall growth within the orthopedic market.

What do you think of the US orthopaedic market and the future? Which trends do you see? Please, let me know in the comments! For more info about how Elos Medtech can help and support you to develop and manufacture trauma, extremities and spine products, visit Elos Medtech’s website. Also, visit our Knowledge Blog to read Onyx Medical – A leading Supplier to the Orthopaedic Market as well as OEM’s Choice of the Right Contact Manufacturer.